موردك الموثوق به للفوسفات الغذائي من الدرجة الغذائية

مرحبًا بكم في شركة Goway، بفضل خبرتنا التي تمتد لعقد من الزمان، أثبتنا أنفسنا كمورد موثوق للفوسفات الغذائي عالي الجودة. ينعكس التزامنا بالتميز في تقنيتنا المتطورة التي تتيح لنا تقديم منتجات متميزة لتلبية متطلبات صناعة الأغذية. في Goway، نفخر في Goway بفريقنا المحترف من الخبراء الذين يمتلكون معرفة وخبرة متعمقة في هذا المجال. يضمن تفانيهم أن منتجاتنا تلبي باستمرار أعلى المعايير ومتطلبات الجودة. عندما تختار Goway، يمكنك الاعتماد على خبرتنا وتجربتنا لتلبية احتياجاتك من الفوسفات الغذائي.

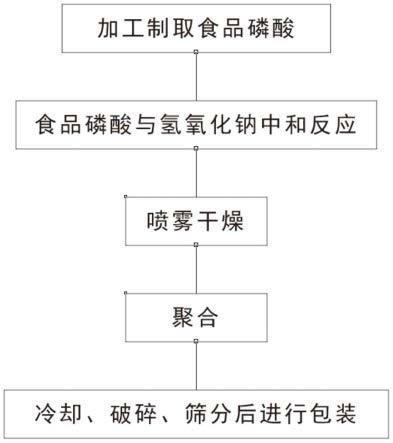

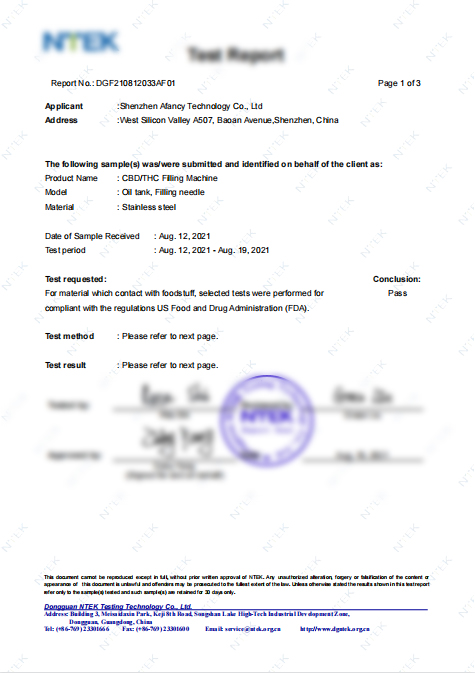

في Goway، الجودة هي أولويتنا. نحن نستخدم تقنيات إنتاج متقدمة وإجراءات صارمة لمراقبة الجودة لضمان تميز منتجاتنا من الفوسفات الغذائي. تتوافق منتجاتنا مع المعايير الدولية لسلامة الأغذية، وقد صُممت منتجاتنا بعناية لتحسين جودة ومذاق المنتجات الغذائية في مختلف الاستخدامات. من التوابل إلى منتجات اللحوم، ومنتجات الألبان إلى المشروبات، تقدم Goway مجموعة شاملة من الفوسفات الغذائي الممتاز المصمم خصيصًا لتلبية احتياجاتك الخاصة. باختيار Goway كمورد لك، يمكنك الحصول على منتجات موثوقة تلبي معايير الصناعة، مما يضمن نجاح ورضا عملائك.

إرسال الاستفسار

-1-300x300.webp)