Enhancing Polyester Dyeing with Alkaline Dyeing Auxiliary and Sodium Hexametaphosphate

Introduction

Discover how the introduction of alkaline dyeing additives, particularly Sodium Hexametaphosphate, revolutionizes polyester fabric dyeing, addressing common issues in the traditional acid-dye bathing method.

Challenges in Traditional Polyester Dyeing

The conventional acid-dye bathing method for polyester fabrics often results in poor quality, low yield, and high production costs. These shortcomings make it less suitable for modern production needs, especially in woven dyeing processes.

Advantages of Alkaline Dyeing Auxiliary Agents

Alkaline dyeing auxiliary agents offer a solution to the limitations of traditional methods. These specialized agents are designed specifically for alkaline dyeing of polyester woven fabrics, providing several benefits:

Enhanced Color Vividness

- By using disperse dyes with excellent alkali resistance, fabrics achieve more vibrant and consistent colors.

Improved Quality

- Alkaline dyeing reduces common defects such as color differences, uneven dyeing, and contamination, leading to higher-quality finished products.

Increased Yield

- The efficiency of the dyeing process is improved, resulting in higher output and reduced production costs.

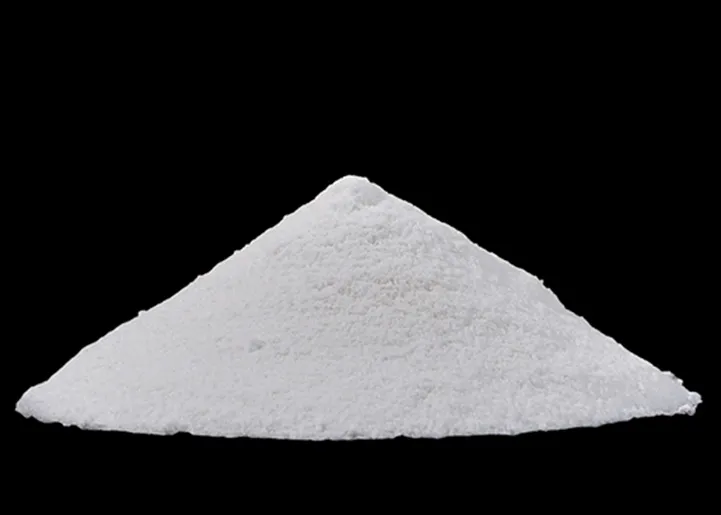

Role of Sodium Hexametaphosphate in Alkaline Dyeing Auxiliary Agents

Alkaline dyeing auxiliaries typically consist of three main components: sodium carbonate, borax, and sodium hexametaphosphate. The composition breakdown is as follows:

- Sodium Carbonate: 22-26%

- Borax: 20-23%

- Sodium Hexametaphosphate: 54-55%

These components are mixed thoroughly by weight percentage, resulting in an alkaline dyeing auxiliary agent suitable for dyeing processes requiring over 60 meters.

Preparation and Use of Alkaline Dyeing Additives

The alkaline dyeing additive is prepared as a solid mixture, which needs to be dissolved in water for application. In solution, it exhibits properties of softening water and dispersion. Sodium Hexametaphosphate plays a crucial role in this mixture by binding metal ions such as calcium and magnesium, thus enhancing the softening and dispersing capabilities of the solution.

Conclusion

The introduction of alkaline dyeing auxiliary agents, particularly those containing sodium hexametaphosphate, significantly improves the dyeing process for polyester fabrics. By addressing the limitations of traditional methods, these additives ensure better quality, higher yield, and reduced costs, making them essential for modern dyeing operations.

FAQ

What are the benefits of using alkaline dyeing auxiliary agents over traditional methods?

- Alkaline dyeing auxiliary agents improve color vividness, reduce defects, increase yield, and lower production costs.

How does sodium hexametaphosphate enhance the dyeing process?

- Sodium hexametaphosphate softens water by binding metal ions and improves the dispersion of dyes, leading to better dyeing results.

What is the typical composition of an alkaline dyeing auxiliary agent?

- An alkaline dyeing auxiliary agent typically consists of 22-26% sodium carbonate, 20-23% borax, and 54-55% sodium hexametaphosphate.

Is the alkaline dyeing additive solid or liquid?

- The alkaline dyeing additive is prepared as a solid and needs to be dissolved in water for use in the dyeing process.