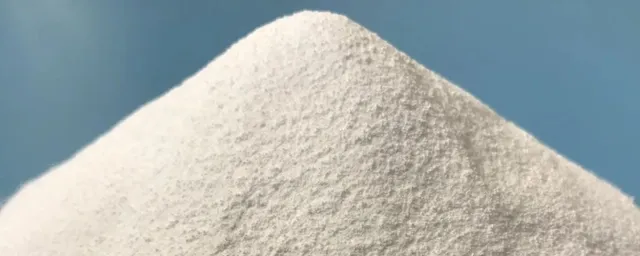

Sodium tripolyphosphate (STPP) is one of the most important builders in modern detergent formulations, widely used in household, institutional, and industrial cleaning products. With its powerful water-softening, chelating, dispersing, and alkaline-buffering capabilities, STPP plays a central role in enhancing washing performance and maintaining detergent stability. This guide provides a comprehensive, industry-focused explanation of how STPP works, where it is used, and why it remains essential in detergent chemistry.

1. What Is STPP and Why It Matters in the Washing Industry

STPP is a multifunctional inorganic phosphate used as a detergent builder—a class of ingredients designed to improve the efficiency of surfactants and support soil removal. In many powder detergents, STPP can account for 10–50% of the formulation due to its synergistic performance benefits, including water softening, emulsification, pH stabilization, and prevention of redeposition. Its versatility makes it valuable across a wide range of cleaning applications, from laundry powders to industrial degreasers.

2. Functional Mechanisms of STPP in Washing Systems

2.1 Chelation of Heavy Metal Ions

Hard water ions such as calcium, magnesium, and iron react with surfactants to form insoluble salts that diminish cleaning power. STPP binds these ions through strong chelation, converting them into stable, non-interfering complexes. This prevents the formation of soap scum, enhances foam performance, and ensures that surfactants remain fully active throughout the wash cycle.

2.2 Soil Suspension and Anti-redeposition

Once soils are lifted from fabrics, preventing them from settling back is critical. STPP helps disperse solid particles and keeps them suspended in the wash liquor. This anti-redeposition function is a key reason STPP is widely used in laundry detergents, especially those intended for heavily soiled fabrics.

2.3 Emulsification of Oils and Proteins

Many soils—including body oils, greases, and protein-based residues—require emulsification before they can be removed. STPP swells and dissolves protein components, promotes emulsification of fatty soils, and enhances detergent penetration into complex dirt structures. It is especially effective in removing lubricating oils and food-related stains.

2.4 pH Buffering and Alkalinity Control

Most detergent systems perform best at a mildly alkaline pH. STPP provides a buffering effect that maintains washing solutions near pH 9.4, optimizing surfactant activity and improving the removal of acidic soils. Stable alkalinity is also crucial for enzyme-based cleaning systems used in premium detergents.

3. Industrial Benefits of Using STPP in Detergent Formulations

- Improved cleaning efficiency in both soft and hard water

- Enhanced compatibility with surfactants and enzymes

- Better product stability during storage and transport

- Increased formulation flexibility for powder detergents

- Reduced detergent dosage while maintaining performance

4. Applications of STPP Across Different Detergent Types

4.1 Powder Laundry Detergents

STPP improves cleaning performance, prevents redeposition, and enhances powder flowability. It is especially useful in high-alkaline laundry formulations for household and institutional use.

4.2 Automatic Dishwashing Powders

Its strong chelating effect prevents scale formation on dishes and machine surfaces, while its dispersing properties improve removal of dried food residues.

4.3 Industrial and Institutional Cleaners

In degreasers and heavy-duty cleaning agents, STPP enhances penetration of oils and greases, making it ideal for food-processing plants, workshops, and commercial laundries.

4.4 Soap-based Systems

STPP prevents the formation of insoluble calcium soaps (soap scum), increasing soap efficiency and improving rinsability.

5. Physical and Chemical Characteristics of STPP

Commercial STPP is available as anhydrous powder or hexahydrate crystals and exists in two structural forms:

- Type I: Rapid hydration and heat release; useful for fast-dissolving detergents.

- Type II: Slower hydration and reduced caking tendency; ideal for humid environments.

Most industrial STPP contains 10–30% Type I to balance solubility and storage stability. Purity, P2O5 content, whiteness, and water insoluble matter are key quality indicators for procurement.

6. Anti-caking Function and Storage Stability

Powder detergents are highly prone to absorbing moisture, leading to lump formation. STPP mitigates this through its ability to form hexahydrate crystals that absorb moisture uniformly. This keeps powder detergents free-flowing and improves shelf life, especially in tropical and high-humidity markets.

7. Comparison of STPP With Other Detergent Builders

| Builder | Key Properties | Performance | Cost | Typical Applications |

|---|---|---|---|---|

| STPP | Strong chelation, dispersion, buffering | ★★★★★ | Moderate | Laundry powders, dishwashing, industrial cleaners |

| SHMP | Excellent dispersion and sequestration | ★★★★☆ | Higher | Premium detergents, industrial uses |

| TSPP | Higher alkalinity | ★★★★ | Moderate | Specialized cleaning formulas |

| Zeolite (phosphate-free) | Environmentally friendly alternative | ★★★ | Moderate–High | Phosphate-free detergents |

8. Environmental Considerations and Phosphate-Free Trends

Regulatory pressure in some regions has encouraged the development of “phosphate-free” detergents using alternatives such as zeolite, sodium citrate, MGDA, and GLDA. Although these options address environmental concerns, they typically do not match STPP’s overall cleaning performance, especially in hard water or heavy-duty cleaning scenarios.

Many markets continue to rely on STPP due to its high efficiency and cost-effectiveness. Manufacturers aiming to improve sustainability can optimize dosage, blend STPP with low-impact builders, or adopt improved wastewater treatment technologies.

9. Procurement Guidelines for Industrial-Grade STPP

For detergent manufacturers, selecting the right STPP supplier is essential. Key considerations include:

- Consistent purity and phase composition

- P2O5 content aligned with formulation needs

- Low insoluble matter for clear solution performance

- Verified COA, MSDS, and quality control documentation

- Technical support for formulation optimization

To ensure stable performance in detergent applications, processors often source product from experienced manufacturers. You can explore high-purity STPP options at our industrial phosphate solutions page.

Conclusion

Sodium tripolyphosphate remains one of the most effective and versatile detergent builders available. Its ability to soften water, disperse soils, emulsify fats, stabilize alkalinity, and prevent caking gives it unmatched performance across a wide range of cleaning applications. While phosphate-free alternatives continue to evolve, STPP remains the backbone of many successful detergent formulations worldwide.

FAQ

What does STPP do in detergents?

STPP enhances cleaning by softening water, dispersing soils, improving alkalinity stability, and preventing caking in powder formulations.

Why is STPP important for hard water washing?

It chelates calcium and magnesium ions, preventing them from reacting with surfactants and reducing cleaning efficiency.

Is STPP used in all types of detergents?

No, but it is widely used in laundry powders, dishwashing detergents, and industrial cleaners.

What is the difference between Type I and Type II STPP?

Type I dissolves quickly and releases heat; Type II hydrates more slowly and resists caking.

Are phosphate-free detergents as effective as STPP-based ones?

Phosphate-free builders exist, but they generally offer lower performance in heavy-duty or hard-water cleaning.

What should manufacturers look for when purchasing STPP?

Purity, P₂O₅ content, phase composition, and consistent quality documentation are key factors.