Goway Chemical Assisting Ceramic Production Cost Reduction and Quality Improvement

Sodium Tripolyphosphate plays the key role of an adhesive in the ceramic industry. Its high-quality solution effect directly affects the cost of raw materials and the attributes of ceramic mud. Goway Chemical, as a professional manufacturer of ceramic Sodium Tripolyphosphate, provides efficient solutions for the ceramic industry through unremitting research and development efforts.

Sodium tripolyphosphate is closely related to the effect of solving agent

As we all know, the decomposition agent is a vital craft in ceramic production. Goway’s chemical ceramic-grade Sodium Tripolyphosphate uses genuine thermos phosphate and authentic soda as raw materials. More than 20 ceramics for internal control indicators have been formulated, and a strict quality control system has been established. This ensures that the product not only has a significant solution effect, but also has less dosage, and the production cost can be effectively reduced.

The relationship between the effect and dosage of the coherent agent

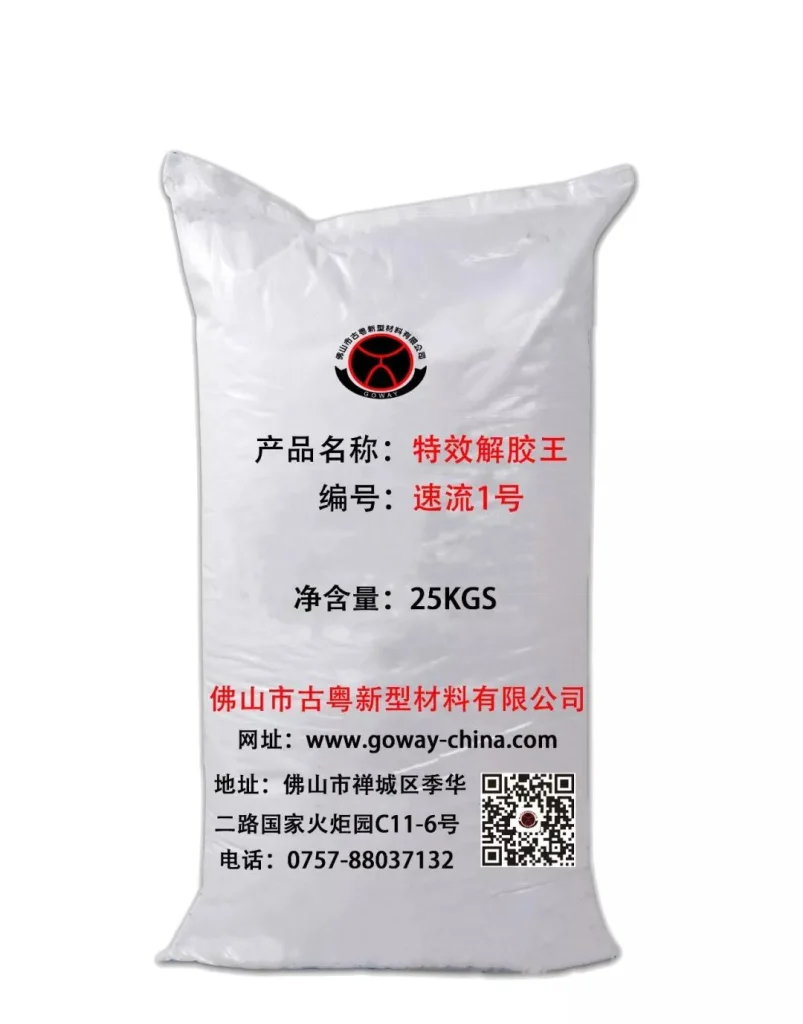

Professional manufacturers in the ceramic industry believe that the effect of the decomposition agent is directly related to the amount. Goway chemical ceramic-grade Sodium Tripolyphosphate has a faster flow rate, less dosage, uniform tile color, and is not easy to break. This provides possibilities for enterprises to use more economically and efficiently in production.

The combination of research and development advantages and custom production

With many years of professional accumulation, Goway Chemical has not only continuously improved product performance through strong research and development advantages, but also actively researched Sodium Tripolyphosphate used by various industries, products, and different enterprises to realize the customized production of rubber. This makes Goway Chemical better meet the needs of different enterprises in the ceramic industry.

Conclusion:

Costed agent, the potential driving force of the ceramic industry

Goway’s chemical ceramic-grade Sodium Tripolyphosphate is not only a decomposition agent, but also an invisible pusher in the ceramic industry. Through the combination of research and development innovation, dosage control, and custom production, this glue-solving agent helps enterprises have more efficient and economical applications in production, creating possibilities for the improvement of the quality improvement and cost of the ceramic industry.

Frequently Asked Questions (FAQ)

Q: What is the main role of Sodium Tripolyphosphate in ceramic production? A: Sodium Tripolyphosphate acts as an adhesive and decomposition agent, improving the solution effect and reducing raw material costs.

Q: How does Goway Chemical ensure the quality of its Sodium Tripolyphosphate? A: Goway Chemical uses genuine thermos phosphate and authentic soda as raw materials, follows over 20 internal control indicators, and implements a strict quality control system.

Q: What benefits does Goway’s Sodium Tripolyphosphate offer to ceramic manufacturers? A: It provides a faster flow rate, requires less dosage, ensures uniform tile color, and reduces the risk of breakage, making production more economical and efficient.

Q: How does Goway Chemical customize its Sodium Tripolyphosphate products? A: Through extensive research and development, Goway Chemical customizes its products to meet the specific needs of different industries and enterprises.

Q: Why is Goway’s Sodium Tripolyphosphate considered a driving force in the ceramic industry? A: Its innovative research and development, precise dosage control, and custom production help improve the efficiency and cost-effectiveness of ceramic production.