Choosing the right phosphate supplier is critical for manufacturers in food processing, detergents, ceramics, water treatment and other industries. Phosphates such as sodium tripolyphosphate (STPP), sodium hexametaphosphate (SHMP), pyrophosphates and other salts directly influence product performance, regulatory compliance and long-term cost. This guide outlines the key criteria to consider when evaluating phosphate suppliers and how Goway Chemical positions itself in this value chain.

Clarify Your Application and Product Scope

The first step is to define clearly which phosphate products and applications you need support for. Typical product families include:

- Food-grade phosphates for meat, seafood, dairy, bakery and beverage products.

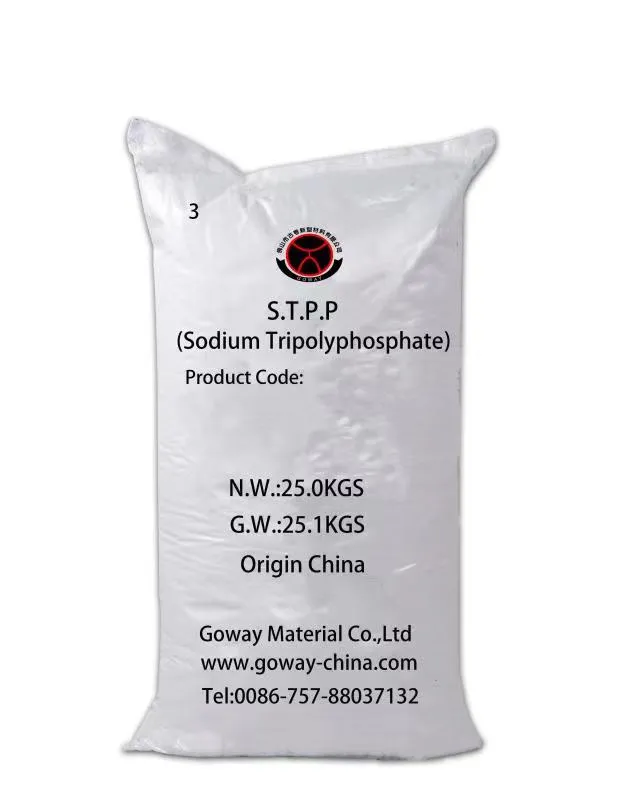

- Industrial phosphates such as STPP, SHMP and TSPP for detergents, ceramics and water treatment.

- Related chemicals such as sodium pyrophosphate, polyphosphates and specialty blends.

Understanding your own application map makes it easier to evaluate whether a supplier can cover your full requirements or only a small portion. Our pages on phosphate for food processing and industrial phosphates and chemicals can help you structure this discussion.

Assess Product Range and Technical Focus

A strong phosphate supplier usually has a focused product range and clear understanding of key application sectors. When evaluating candidates, consider:

- Whether they supply both food-grade and industrial-grade phosphates, or specialize in one area.

- Experience in your specific industry segment (for example meat processing, detergents or ceramics).

- Ability to offer multiple related products (STPP, SHMP, pyrophosphates) rather than a single item only.

Suppliers with a coherent product portfolio are often better prepared to provide consistent quality and technical support across different projects.

Review Specifications and Quality Control

Quality consistency is a key factor in phosphate sourcing. Buyers should:

- Request detailed specifications for each product, including P2O5 content, pH, insoluble matter and impurity limits.

- Review certificates of analysis (COA) and understand which parameters are tested on every batch.

- Check whether the supplier operates under recognized quality systems and has experience with third-party audits if needed.

For food-grade phosphates, heavy metals, microbiological limits and compliance with relevant food standards are essential. For industrial-grade phosphates, consistency in functional performance and physical characteristics is often the main focus.

Documentation and Regulatory Support

Reliable suppliers provide comprehensive documentation to support regulatory compliance and customer audits. This typically includes:

- COA and SDS/MSDS for each product.

- Statements regarding food-grade status where applicable.

- Information on compliance with key regulations in target markets.

For manufacturers serving export markets, it is important to confirm that documentation is available in appropriate languages and formats.

Evaluate Logistics, Packaging and Service

A technically suitable product still needs to be delivered reliably. When assessing suppliers, consider:

- Available packaging options, such as 25 kg bags, jumbo bags and customized packaging.

- Lead times for regular orders and flexibility for urgent shipments.

- Experience with container loading, palletization and export documentation.

Well-designed packaging and logistics help protect product quality and simplify handling at your facilities.

Pricing vs. Total Cost of Ownership

Unit price is only one part of the total cost of owning phosphate products. Buyers should also consider:

- Product performance and dosage required to reach target results.

- Impact on process efficiency, such as water savings, yield improvement or reduced waste.

- Indirect costs related to quality issues, returns or formulation instability.

Choosing the lowest initial price without regard to performance and reliability can be more expensive over time than working with a trusted partner at a stable, competitive price level.

Trial Support and Technical Communication

For new projects, laboratory and plant trials are essential. Suppliers that actively support this process provide added value by:

- Supplying samples promptly.

- Sharing application data and suggested dosage ranges.

- Reviewing trial results with you and recommending refinements.

Good technical communication helps reduce project risk and speeds up qualification.

Why Work with Goway Chemical as a Phosphate Supplier

Goway Chemical focuses on phosphates for both food and industrial applications, including STPP, SHMP, pyrophosphates and related products. Our approach includes:

- A clear product line covering major phosphate families for food and industry.

- Attention to specification stability and batch-to-batch consistency.

- Support for documentation and regulatory questions in key export markets.

- Flexible packaging and logistics solutions for different order sizes.

We aim to build long-term cooperation with customers, rather than short-term transactions, and are prepared to support sample evaluation, formulation optimization and ongoing technical dialogue.

Frequently Asked Questions

Should I choose a supplier that offers all phosphate types?

Not necessarily. It is more important that the supplier has strong capabilities in the specific phosphates and applications you rely on. However, being able to supply related products such as STPP, SHMP and pyrophosphates can simplify sourcing and coordination.

How can I compare quality between different phosphate suppliers?

Ask for detailed specifications, recent COAs and, if possible, run comparative performance tests in your own formulations. Evaluating both analytical data and practical results is the best way to compare.

Is it better to work directly with a manufacturer or through a distributor?

Both models can work. Direct manufacturer relationships may offer more technical detail and tailored solutions, while distributors can provide local stock and support. The right choice depends on your location, volume and service expectations.

What information should I prepare before contacting a phosphate supplier?

It helps to provide information on your application, annual volume, quality requirements, target markets and any specific regulatory or documentation needs. This allows the supplier to respond with relevant product recommendations and commercial terms.