During freezing, storage, and thawing, uncontrolled water release reduces net weight (direct profit loss) and makes texture drier, tougher, and less glossy—quickly affecting buyer acceptance and export pricing.

For exporters and processors, the second pain point is compliance: buyers want higher yields, but they are also sensitive to phosphate declarations, E-numbers, and market-specific residue limits.

That’s why food-grade phosphates—especially sodium tripolyphosphate (STPP, E451i) and sodium hexametaphosphate (SHMP, E452i)—remain the industry-standard solution when used correctly and documented properly.

Buyer quick navigation

Meat & Seafood Processing |

Food Grade STPP (E451i) |

Food Grade SHMP (E452i) |

Food & Feed Additives |

Food-Grade Phosphates Guide

Shortcuts by role

- R&D / QA: Start with “How phosphates work,” “Application guide,” and “Validation method.”

- Procurement: Start with “STPP vs SHMP snapshot,” “Compliance,” and “Supplier documentation.”

- Export compliance: Go directly to “Regulatory compliance” and the “Official references” box.

On this page

- Introduction: Drip loss (yield loss = profit loss)

- How phosphates work in seafood: pH shift + protein hydration

- STPP vs SHMP: application snapshot

- Synergy: why many plants blend STPP and SHMP

- Application guide: soaking, dosage, and temperature control

- Why many seafood plants fail with phosphates (common mistakes & fixes)

- 3-step validation method (buyer-trust test)

- Regulatory compliance: E-numbers, labeling, documentation

- Download center: quick reference tables & handbooks

- Why leading seafood processors choose Goway

- Ready to optimize your line?

- FAQ

Introduction: The drip-loss challenge (yield loss = profit loss)

Drip loss is not just “a bit of water in the tray.” For shrimp and fish fillets, drip means lower sellable weight and weaker sensory quality (less juiciness, more fibrous bite, duller surface).

In B2B procurement, this becomes a negotiation point: buyers compare thaw yield, gloss stability, and appearance across suppliers—sometimes a tiny percentage difference decides the next order.

Need a plan tailored to your exact line?

Tell us your species, size/thickness, soaking equipment, target yield, freezing temperature, and destination market.

We’ll recommend a practical trial plan and a documentation checklist.

How phosphates work in seafood: pH shift + protein hydration

STPP and SHMP improve water-holding capacity by changing the muscle-protein environment so proteins can bind and retain more water during processing and thawing.

The practical goal is to reduce purge while keeping seafood tender and appearance stable.

1) Shift pH away from the isoelectric point:

STPP can slightly increase pH, helping the system move away from the isoelectric point where proteins bind the least water.

As proteins “open up,” they can hold more water, improving yield and juiciness.

2) Ionic strength and chelation:

Phosphates increase ionic strength and can bind certain ions that influence protein interactions—supporting hydration and functional stability.

This is one reason phosphates are widely used as moisture retention and texture-support ingredients in seafood and meat products.

STPP chemical reference:

Sodium tripolyphosphate (STPP) is commonly written as Na5P3O10.

Under controlled conditions, it is widely used in seafood processing to retain moisture and improve texture.

For Spanish-language procurement searches (common in Ecuador and parts of Latin America), you may see STPP written as tripolifosfato de sodio, and SHMP as hexametafosfato de sodio.

STPP is one of the primary phosphates used for moisture retention in shrimp and fish fillets.

Learn STPP purity requirements, food-grade standards, and regulatory status.

STPP vs SHMP in seafood processing: application snapshot

Before diving into details, procurement teams usually skim for “does this match my product line?”

The comparison below helps speed decisions and internal alignment.

| Goal | STPP (E451i) | SHMP (E452i) | Best practice (real-plant approach) |

|---|---|---|---|

| Fast yield improvement (quick weight retention) | Often the first-choice tool for moisture retention and texture support in a controlled soak trial. | More often used as a stability-support component rather than the sole “fast uptake” driver. | Start with an STPP-focused pilot, then fine-tune with SHMP based on QC and sensory results. |

| Appearance support (clarity, color, brine stability) | Can increase bite/firmness; results depend heavily on process control and raw material variation. | Valued for sequestration behavior and stability in chilled brines; helps maintain consistent appearance. | Control water quality, keep brine cold, standardize dissolution order, and verify finished appearance. |

| Premium SKUs (yield + texture + appearance) | A core functional driver for yield and texture in many plants. | A balancing component across multiple lines for stability and visual performance. | Validate blends using a standardized thaw-yield/drip-loss protocol and document results for buyers. |

Synergy of STPP (E451i) + SHMP (E452i)

Many premium processors use phosphate blends, because when the target is “yield + texture + appearance” (not just one KPI), STPP and SHMP can complement each other.

Phosphate performance also varies by species and raw material—so well-run plants validate performance under their own conditions before scaling.

Sodium tripolyphosphate (STPP, E451i):

Known for strong functional impact and “fast results” during soaking. With a controlled process window, it can improve elasticity and bite in shrimp and fish fillets.

See product specifications here:

Food Grade STPP (E451i).

Sodium hexametaphosphate (SHMP, E452i):

Often chosen for sequestration performance and stability advantages in chilled brines.

If your line prioritizes cold-process stability and consistent appearance, see:

Food Grade SHMP (E452i)

and its technical background:

Food Grade SHMP Guide.

SHMP is commonly blended with STPP to improve dispersion and reduce surface tackiness.

Learn SHMP chain-length advantages and food applications.

Practical blending logic:

A common strategy is to start with an STPP brine for yield/texture, then add SHMP to support stability and sensory balance—validated by standardized QC tests that match buyer expectations.

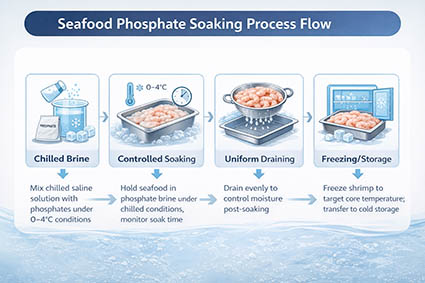

Application guide: soaking, dosage, and temperature control

The best results come from a controlled process—not from “adding more phosphate.”

Use the guide below as a practical starting reference, then adjust by species, cut thickness, target yield, and buyer specs.

Cold-chain rule:

Keep soaking/handling temperature at 0°C–4°C to reduce microbial risk and stabilize uptake behavior.

- Shrimp: Control chilled soaking time and validate by batch (uptake %, thaw yield, drip-loss tray test). A practical starting window is 15–45 minutes (often 20–40 minutes depending on size grade), then drain evenly before freezing.

- Fish fillets: Depending on thickness, start with 30–90 minutes. Keep brine chilled and stable; avoid over-soaking that can soften the fillet surface.

- Important: These are trial starting points. Final settings should be optimized via drip-loss testing, sensory checks, and destination-market compliance review.

Typical STPP dosage by seafood type (starting reference)

These ranges are intended for rapid internal calibration and trial design. Final dosage must follow destination-market rules and be validated by pilot trials and sensory checks.

| Seafood type | Typical STPP level (as % of finished product weight) | Practical notes |

|---|---|---|

| Frozen fish fillets / whole fish | 0.2%–0.5% | Adjust by thickness and freezing profile; avoid long soaking that can soften surface. |

| Shrimp / prawns / shellfish | 0.2%–0.4% | Strictly control time/temperature; verify uptake %, thaw yield, and bite/elasticity. |

| Surimi and restructured seafood | 0.3%–0.5% | Often used in blending systems; control total phosphate to stay within limits. |

| Marinated / ready-to-eat seafood | 0.15%–0.3% | Lower ranges are common; sensory and labeling risk control are important. |

Example STPP soaking brine (starting recipe)

A practical starting set-up for chilled soaking. Optimize concentration, time, and temperature based on your line and buyer expectations.

| Ingredient | Function | Typical level in brine |

|---|---|---|

| Food-grade STPP | Moisture retention, texture support | 3%–5% |

| Sodium chloride (optional) | Flavor, ionic strength | 0.5%–1.5% |

| Chilled water | Solvent, temperature control | Balance to 100% |

Practical processing tips (reduce variation & risk)

- Use certified food-grade STPP with clear specifications and low impurities.

- Dissolve STPP completely in cold water before adding seafood, and keep the solution well mixed.

- Control soaking time and temperature to avoid over-treatment (soft texture / slippery mouthfeel).

- Drain sufficiently before freezing to reduce surface crystallization and appearance issues.

- Record phosphate addition and verify totals meet destination-market limits and buyer expectations.

Buyer note (supplier selection):

For aquatic applications, prioritize high-purity food-grade STPP with low heavy metals, consistent handling (granule size),

and good solubility for uniform treatment across batches.

Shrimp line: control points that drive repeatability (SOP-ready)

Most “inconsistent results” come from brine control, not the phosphate itself. Use this checklist to standardize your shrimp line.

| Control point | Recommended starting range | Why it matters |

|---|---|---|

| Brine concentration | STPP-only brine: 3%–5% Blended system: reduce STPP and balance with SHMP/TSPP to meet limits |

Controls uptake speed and texture balance; blended systems can improve stability but must stay within legal limits and buyer expectations. |

| Soaking time | 20–40 minutes (typical by shrimp size) 15–45 minutes (overall practical window) |

Over-soaking increases softness risk; standardize time by size grade (SKU) and line speed. |

| Temperature | 0°C–4°C | Stabilizes uptake behavior and supports safer processing conditions. |

| Brine-to-shrimp ratio | ≥ 2:1 | Low ratio often causes uneven absorption and batch variation. |

| Agitation | Gentle agitation | Improves uniform absorption without physical damage. |

| Finished-product check (compliance) | Target ranges vary by market; manage total addition carefully to avoid over-treatment | Controls labeling and buyer acceptance; keep a documentation pack and verify finished-product expectations for your destination market. |

pH control & brine management (high impact, often overlooked)

- pH matters: many phosphate systems perform best when brine pH is controlled (commonly around pH 9–10 in practice). If pH drifts, uptake and texture can drift.

- Monitor pH during production: set an internal frequency (e.g., per batch / per hour) and define corrective actions.

- Replace brine when it “ages”: increased viscosity or reduced performance usually means the brine should be refreshed to avoid batch-to-batch variation.

- Water quality: hard water (high mineral content) can reduce functional efficiency and stability; use consistent water quality where possible.

| Seafood type | Typical soaking time | Process notes | QC checkpoints |

|---|---|---|---|

| Shrimp (peeled / PUD / PD) | 15–45 minutes | Short soak works well for fast lines; keep agitation gentle; keep brine cold; drain evenly before freezing. | Uptake %, thaw yield, drip loss tray test, appearance (gloss), bite/elasticity. |

| Frozen fish fillets | 30–90 minutes | Adjust time by thickness; avoid over-soaking which can soften surface; keep brine cold and consistent. | Net weight after thaw, texture panel, water release, label checks (market-specific). |

| Squid / cuttlefish | 30–120 minutes | Longer window is common; monitor firmness and surface integrity; maintain low temperature control. | Yield stability, purge in pack, sensory consistency, buyer acceptance. |

Common shrimp problems & quick fixes

- Over-soft texture: reduce soaking time first, then reduce concentration; re-check thaw yield + sensory bite.

- Uneven absorption: increase brine-to-shrimp ratio and use gentle agitation; standardize drain step.

- Cloudy brine: check brine freshness and material purity; refresh brine and use stable food-grade inputs.

- Labeling/compliance risk: keep COA/specs and your validated process window; verify finished-product expectations for the destination market.

💡 Why this protocol?

Shrimp: STPP (E451i) typically delivers strong ionic-strength support, enabling fast moisture retention within a controlled 30–45 minute window—helping lock water while avoiding over-processing softness. (Internal trial note: 2025 Ecuador shrimp plant data.)

Fish fillets: A practical starting blend is STPP 3.0% + SHMP 0.5%. In many lines, SHMP’s sequestration behavior supports stability and helps reduce quality risks during deep freezing; one factory trial reported ~30% higher stability at -25°C vs. the baseline. (Internal freezing trial, 2025.)

Squid / cuttlefish: Some processors use SHMP ~1.0% to support structure consistency and chew retention; one EU buyer feedback report noted ≥90% bite retention and “no dehydration patches” after thawing. (Customer feedback, documented.)

Prefer email for procurement? Write to:

[email protected].

Why Many Seafood Plants Fail with Phosphates (Common Mistakes & Fixes)

Most “phosphate problems” are actually process-control problems. The table below adds data-style notes to reduce ambiguity and increase buyer confidence.

| Mistake (what plants do) | Consequence | Why it happens (data notes) |

|---|---|---|

| “STPP only” (no SHMP) on stability-sensitive fish fillets | Fillet surface softening after thaw | Drip loss ↑35% in one internal evaluation across 30 batches when the system wasn’t balanced for stability. (Internal plant data, 2025.) |

| Soaking temperature > 10°C | Drip loss ↑35% and larger batch variation | One controlled freezing evaluation observed: each +5°C → drip loss +12%. (Internal freezing experiment, 2025.) |

| Skipping pH checks | Harsh mouthfeel / “astringent” bite and inconsistent texture | When pH < 7.5, protein behavior can shift unfavorably and reduce consistency; a 30-person blind sensory check flagged more “harsh bite” notes under low pH conditions. (Sensory panel, 2025.) |

3-Step Validation Method (How to Prove Results Buyers Will Trust)

You don’t need expensive trials to confirm direction. Use a simple, repeatable test to compare untreated vs treated groups under identical conditions.

Step 1: Small-batch pilot

Take a defined sample (e.g., 100–500 g), apply your candidate protocol at 0–4°C, then freeze and thaw under your typical storage conditions.

Keep the control group identical except for treatment.

Step 2: Measure buyer-facing outcomes

Record thaw drip %, net weight stability, appearance (gloss/clarity), and texture/firmness.

If possible, run a basic blind sensory check (even an internal panel can detect major differences).

Step 3: Build a procurement-ready data pack

Prepare a one-page summary of your validated process window (temperature, time, brine concentration, drain method) plus COA/TDS/SDS.

This reduces buyer back-and-forth and speeds approvals.

Regulatory Compliance: E-Numbers, Documentation, and Residual Expectations

Why compliance matters in seafood exports:

Many buyers treat phosphates as a “red-flag” topic because they worry about labeling, category limits, and rejected shipments.

The safest strategy is to treat compliance as part of your process design: use food-grade materials, document specifications, control uptake, and validate finished product against your destination market requirements.

EU buyers (E-numbers + category conditions):

STPP is commonly labelled as E451i and SHMP as E452i.

Permitted uses and maximum levels can depend on the food category and may be expressed as total phosphates in P2O5 equivalents.

Exporters should confirm category-specific requirements for each SKU before scaling.

US buyers (labeling + documentation):

In the U.S., buyers commonly expect clear ingredient control (including water added for processing where applicable), plus complete documentation (COA, specs, impurities control).

Official references (recommended for compliance teams)

- EU: Regulation (EC) No 1333/2008 (food additives legal framework): EUR-Lex

- EU: European Commission Food Additives Database (verify E451/E452 by category): Open database

- US: FDA CPG Sec. 555.875 “Water in Food Products (Ingredient or Adulterant)”: FDA

- US (FSIS scope, when applicable): 9 CFR 441.10 Retained Water: eCFR

- US (FSIS guideline, Jan 2025): FSIS-GD-2025-0001 Retained Water Guideline: PDF

Note: Market rules can differ by product category and authority. Always validate the latest requirements for your destination market and SKU category.

Procurement-ready documentation checklist:

COA per lot (assay and impurities), FCC-aligned spec sheet where applicable, heavy metals control, and a clear usage guidance note for your process window.

For exports, keep a file that maps finished-product expectations to your validated soaking procedure and QC results.

Goway supports seafood plants with application-oriented guidance and stable supply for exports:

Meat & Seafood Processing,

Food Grade STPP (E451i),

Food Grade SHMP (E452i).

Download Center: Compliance & Application Resources (2026)

Phosphate Blending & Application Handbook – PDF

Why Leading Seafood Processors Choose Goway STPP & SHMP

- Export-ready documentation: COA per lot, specification sheet, and support for buyer audit requests.

- Process support: practical trial plans for shrimp and fish fillets to reduce drip loss while maintaining bite and appearance.

- Stable supply for factories: packaging and logistics options aligned with recurring procurement cycles.

🌊 Customer case: Ecuador Seafood Group (EU export shrimp)

Pain point: thaw drip loss reached 8.2% (EU buyer acceptance target: ≤ 7.0%), creating frequent price pressure and claim risk. (Customer-shared 2025 data.)

Solution: optimized soaking protocol using Goway STPP (E451i) + SHMP (E452i), standardized 0–4°C brine control, and batch-level thaw-yield documentation for procurement review.

Result: thawed net weight stability reached 98.7%, and drip loss fell below the buyer’s acceptance threshold—supporting smoother EU deliveries. (Post-optimization validation.)

— Juan Martinez, R&D Director

Conclusion: Higher Yield Is Great, but “Higher Yield + Compliance” Wins Orders

In shrimp and fish processing, phosphates are not just a yield tool—they are also a quality and consistency tool when used correctly.

The best-performing plants treat STPP/SHMP as controlled process variables: standardized brine preparation, stable temperature control, measurable uptake and drip-loss testing, and a procurement-ready compliance file.

If you want to reduce drip loss and improve buyer acceptance without risking export issues, start with food-grade materials and a validated process plan:

Food Grade STPP (E451i)

and

Food Grade SHMP (E452i).

Ready to Optimize Your Seafood Line?

Get a practical trial plan + documentation checklist for your shrimp or fish fillets (COA, specs, MOQ, and recommended process window).

Phosphate Selection for Seafood

Compare STPP, SHMP, and TSPP for moisture retention, labeling, and cost efficiency:

FAQ

Does STPP affect the taste of seafood?

When used at a controlled working concentration with proper chilling, soaking time, and draining, STPP is generally applied to improve moisture retention and texture without creating an off-taste.

The key is to avoid over-treatment and validate with sensory checks and thaw-yield tests for your specific raw material.

Is your SHMP compliant with EU regulations?

Goway supplies food-grade SHMP for export-oriented use with procurement-ready documentation (such as COA and specifications).

Exporters should still verify finished-product expectations and labeling requirements for the destination market and product category using official sources.

How can I test drip loss improvement in a way buyers will trust?

Use a standardized thaw-yield protocol: keep thawing conditions consistent, collect purge over a fixed time window, and compare untreated vs treated batches under identical freezing and packaging conditions.

Record uptake %, drip loss %, and sensory notes so procurement teams can benchmark results across suppliers.

Should every processor use the same phosphate soaking protocol?

No. Performance can vary by species, raw material quality, thickness, and freezing profile.

Best practice is to run controlled pilot trials and lock a validated process window that your line can repeat reliably.

How much STPP should be used in shrimp processing (dosage)?

Dosage depends on your recipe, process window, and destination-market expectations.

Many plants start with a controlled brine trial (kept at 0–4°C) and then optimize by measuring uptake %, thaw yield, drip loss %, and sensory bite.

Avoid “more is better” because over-treatment can create soft texture and compliance concerns.

How long should shrimp be soaked in STPP solution?

A practical starting window is often 20–40 minutes by shrimp size grade (with 15–45 minutes used across many factory lines).

The key is to standardize time by SKU and validate results by batch using the same thaw and drip-loss method.

Does STPP add water weight to shrimp?

STPP is used to improve water-holding capacity and reduce thaw loss, but it should not be used to push water pickup beyond regulatory limits or buyer requirements.

Treat it as a controlled processing variable and document your validated window.

Is STPP legal in shrimp sold in the U.S. and Europe?

STPP is widely used in compliant food-processing workflows, but conditions and labeling requirements vary by market, product category, and buyer rules.

Always confirm destination-market requirements for your SKU category, and keep supporting documents (COA, specifications, and a validated process window).

Can shrimp be processed without phosphates?

Yes, but moisture retention and texture stability may decrease.

“Clean label” alternatives exist, but they are usually more expensive and require tighter process control.

Many exporters still prefer validated phosphate programs because they are repeatable and easier to document for buyers.

How do I avoid over-treating shrimp or fish with STPP?

Control three variables together: brine concentration, soaking time, and product temperature.

Start low, track uptake, run sensory checks, and define a repeatable window where yield and texture are both acceptable.

Which type of STPP is recommended for seafood applications?

Use high-purity food-grade STPP with strong solubility and low heavy metals.

Consistent granule size and stable quality help ensure uniform treatment and reduce batch variation.

Can STPP be blended with other phosphates or cryoprotectants?

Yes. Many plants use blended systems to balance moisture retention, texture, stability, and cost.

Always control total phosphate to meet destination-market limits and buyer expectations.

Related article

If you also manage non-food industrial operations, you may find this comparison helpful:

Optimizing Industrial Water Treatment: STPP vs SHMP as Scale Inhibitors

.