Import Compliance Risk Alert (What Causes Rejections)

Food buyers get rejected most often for three reasons: (1) wrong grade (industrial SHMP used for food), (2) missing batch traceability (no COA / inconsistent lots), and (3) impurity limits (fluoride / heavy metals not aligned with destination-market specs).

What we provide (risk-control pack):

- Batch COA for every shipment (lot number traceable to production record)

- Market-specific spec matching (GB / EU 231/2012 / buyer limits)

- Optional third-party testing (SGS/Intertek) for first order or audit needs

Low-risk next steps:

Tip: If your destination is EU/UK, send your required impurity limits first. We will confirm by COA before shipment.

Our Food Grade Sodium Hexametaphosphate (SHMP) is designed for audit-ready food compliance and stable batch quality. It is used as a stabilizer, emulsifier, and sequestrant to help protect texture, color, and shelf-life performance in seafood, meat, dairy, and beverage applications.

E-Number: E452(i) | INS No.: 452(i) | Grade: Food / E452i (FCC documentation available upon request)

Standards: GB 1886 series (food additive) and/or destination-market specification. Final shipped-batch values are subject to COA.

Key Specifications (Food Grade E452i) — Market-Specific Compliance Matrix

To reduce import risk, buyers should align specs to the destination-market purity criteria. Below is a practical matrix you can use during supplier qualification and first-order QA review.

| Item | Goway Standard Supply (typical) | GB 1886.4-2020 (reference) | EU 231/2012 (if required) |

|---|---|---|---|

| Total Phosphate (as P2O5) | 68.0% Min | ≥ 67.0% | 60–71% (on ignited basis) |

| Inactive Phosphate (as P2O5) | 7.5% Max | ≤ 7.5% | Assay definition-based (buyer confirms) |

| Arsenic (As) | ≤ 3 mg/kg (3 ppm) | ≤ 3 mg/kg | ≤ 1 mg/kg (EU-compliant grade on request) |

| Lead (Pb) | ≤ 1 mg/kg (1 ppm) | ≤ 4 mg/kg | ≤ 1 mg/kg |

| Fluoride (F) | ≤ 30 mg/kg (30 ppm) | ≤ 0.003% (≈ 30 mg/kg) | ≤ 10 mg/kg (EU-compliant grade on request) |

| pH Value (1% solution) | 5.8 – 6.5 (strictly controlled) | 5.0 – 7.5 (10 g/L solution) | 3.0 – 9.0 (1% solution) |

| Water Insoluble | 0.05% Max | ≤ 0.06% | ≤ 0.1% |

Notes: The “EU 231/2012” column is provided for destination-market alignment. If you require EU/UK compliance, request EU-compliant grade and confirm with the latest batch COA before shipment.

Food Industry Applications

1) Seafood & Meat Processing (Surimi / Shrimp / Fish / Meat)

Helps reduce drip loss during freezing/thawing, supports texture stability and sliceability, and helps protect color by binding metal ions. Commonly used in surimi, shrimp, and fish processing systems. (See also: Meat & Seafood Processing Solutions)

2) Beverages & Juices

Helps reduce turbidity and supports color stability by binding metal ions that can trigger haze or precipitation in formula-dependent systems.

3) Dairy Products

Helps reduce protein precipitation and phase separation in processed dairy systems such as canned milk, coffee creamer, and related applications, improving smoothness and stability.

4) Canned Foods & Processed Fruits/Vegetables

Supports pigment stability and helps reduce discoloration by controlling metal ions during processing and storage.

Food Industry ROI (How Buyers Measure Value)

Procurement teams typically approve a new phosphate supplier only when QA can verify compliance and the plant can quantify gains. Use this KPI sheet to run a quick trial and report results internally.

| Application | Buyer Pain Point | Suggested Trial Setup (example) | KPIs to Report (target) |

|---|---|---|---|

| Surimi / Seafood | High drip loss after thawing | SHMP 0.20–0.35% (optimize by recipe); compare vs current supplier | Drip loss (%) ↓, yield ↑, texture score ↑ (n≥10 batches) |

| Dairy / Creamer | Protein precipitation / phase separation complaints | SHMP 0.10–0.20% (formula-dependent); validate heat stability | Sediment (mg/100ml) ↓, complaint rate ↓, viscosity stability ↑ |

| Beverages | Haze / turbidity out of spec | Dose to bind metal ions; run shelf-life haze test vs control | Turbidity (NTU) ↓, transmittance ↑, color stability ↑ |

Note: Suggested dosages and KPI targets are for trial planning and internal reporting. Final usage levels must comply with local regulations and your finished-product specs.

Compliance & Quality Assurance (Audit Pack Ready)

- Traceability: Lot number on packaging + batch records; COA attached to every shipment.

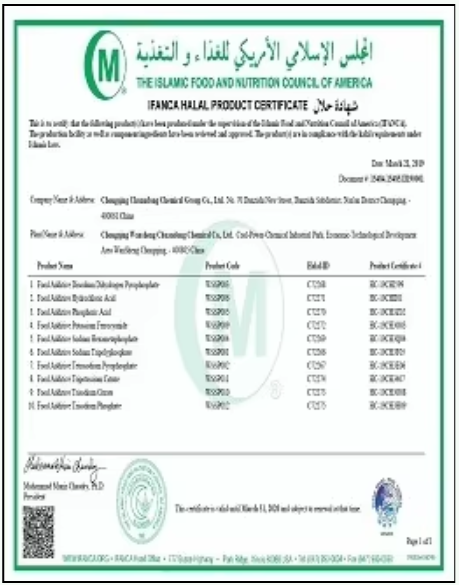

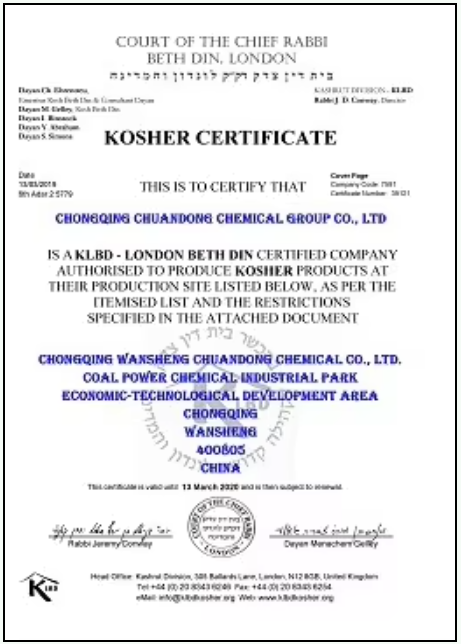

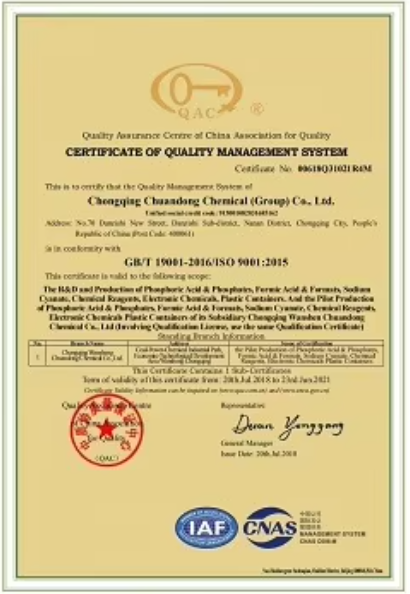

- Documents: COA + SDS/MSDS; HALAL/KOSHER and ISO 22000 / HACCP documents available for compliance review upon request.

- Market matching: GB 1886 series by default; EU 231/2012 or buyer-specific impurity limits can be matched by request (confirmed by COA).

- First order risk control: Optional third-party test report (SGS/Intertek) for audit or import clearance confidence.

- Clean packaging: 25 kg food-grade inner-lined bags; export packaging options available.

Certificates

Click logos to view certificate files. For audit packs, request the full document set (COA sample + SDS + certificates + QA statements).

Choose Your Next Step (Lower-Risk Buying Path)

Different stakeholders need different proof. Use the right CTA to move faster: QA gets documents, R&D gets samples, procurement gets contract pricing.

For Lab / R&D Validation

Request a free sample (200g) to run your drip-loss, stability, and haze tests.

For QA / Compliance Review

Download a buyer-ready COA template and request the latest batch COA for your destination market.

For Procurement / Long-Term Supply

Get an annual contract quote with stable lead time, packaging, and destination-port terms.

Buyer Resources (for Faster Internal Approval)

- Food-Grade Phosphates: Functions, Types & Applications in Modern Food Processing

- Seafood Processing Guide: How STPP & SHMP Improve Moisture Retention and Reduce Drip Loss

- Phosphates Encyclopedia: Types, Chemistry & Uses (for QA terminology and internal review)

These references help QA, regulatory, and R&D teams align terminology, use-case logic, and documentation requirements during supplier qualification and first-order approval.

Food Grade SHMP FAQ

Is your SHMP compliant with E452(i) and FCC grade requirements?

Our product is supplied for E452(i) applications, and FCC documentation can be provided upon request. Please share your destination market and internal specification so we can match the correct standard and provide the latest batch COA.

Do you support EU/UK compliance (EU 231/2012) for impurity limits?

Yes, we can support destination-market compliance workflows. If your market requires EU 231/2012 limits (e.g., tighter fluoride and heavy metal criteria), request an EU-compliant grade and we will confirm by batch COA prior to shipment.

Can you provide a free sample for lab testing?

Yes. Samples (typically 200g) are available for lab validation and trial runs. Contact us with your application, dosage range, and destination market so we can prepare the right grade and documents.

What dosage should we use for surimi or seafood processing?

Dosage depends on recipe, process, and local regulations. As a trial reference, many buyers start within 0.20–0.35% and optimize against drip loss, yield, and texture KPIs. Request a trial protocol and KPI sheet for your product type.

How do we verify “real E452(i)” on a COA?

Ask for a batch COA showing key assay items (P2O5, inactive phosphate), impurity limits (As/Pb/F), and traceable batch/lot number. You can also standardize QA review using our E452(i) COA template.

What is the shelf life and recommended storage?

Typical shelf life is 24 months in original unopened packaging. Store in a cool, dry, clean environment and keep sealed to avoid moisture absorption.

Downloads

Get Food-Grade SHMP Quote

To quote quickly, please share: destination market, required standard (GB / EU 231/2012 / FCC), As/Pb/F limits, packaging, annual demand, and destination port.