Food & Feed Additives

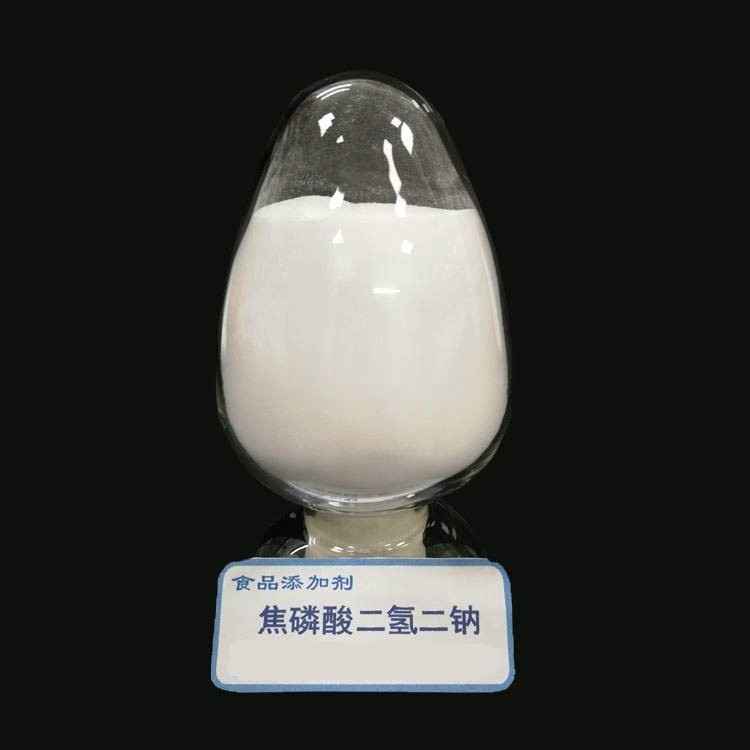

Sodium Acid Pyrophosphate (SAPP)

Food-Grade Leavening Acid | CAS 7758-16-9 | Slow-Acting, Heat-Activated

✅ FDA 21 CFR 182.1784*

✅ EU E450(i) Approved*

✅ Halal & Kosher*

*Certificates & compliance documents available upon request. Specifications may vary by grade/market requirements.

Why Choose SAPP for Your Formulations?

Designed for predictable, controlled gas release during baking. SAPP helps R&D teams hit consistent texture and volume,

while helping procurement teams secure compliant, reliable supply.

Predictable Rise

Gas release peaks at 60–90°C — ideal for cakes, muffins & pancakes.

No Bitter Aftertaste

Neutralizes sodium bicarbonate effectively, helping avoid metallic or bitter notes.

Extended Shelf-Life Support

Helps stabilize pH in refrigerated/frozen dough systems during storage.

Meat Processing Bonus

Enhances water binding in injected poultry when blended with STPP (application-dependent).

Technical Specifications

Typical specification for food-grade SAPP. We can align to your required standard (e.g., GB 1886.341-2022,

FCC, or other market standards) based on destination and application.

Note: Please confirm required grade/spec with your regulatory team. Final COA values are batch-specific.

💡 Typical Usage Level

- Bakery: 0.5–2.0% of flour weight

(with NaHCO₃ at 1:1 to 1:1.2 ratio, by neutralizing value) - Meat Injection: 0.1–0.3% in brine solution

(often blended with STPP, application-dependent)

These ranges are formulation-dependent. Please share your process conditions (temperature profile, storage, target texture/yield) and destination market requirements for optimized guidance.

| Parameter | Specification |

|---|---|

| Chemical Formula | Na₂H₂P₂O₇ |

| Appearance | White crystalline powder |

| Assay (as P₂O₅) | ≥ 62.0% |

| pH (1% solution) | 3.5 – 4.5 |

| Loss on Drying | ≤ 0.5% |

| Heavy Metals (as Pb) | ≤ 10 ppm |

| Fluoride | ≤ 50 ppm |

| Mesh Size | 20–60 (or as per customer request) |

Applications

Clear, practical use-cases—so your team can quickly confirm fit and move to trials.

Bakery Leavening

A slow-acting, heat-activated leavening acid that releases CO₂ primarily during baking

(60–90°C), ensuring optimal volume and crumb structure in cakes and muffins.

Typical products: cakes, muffins, pancakes, self-rising flour.

Frozen Dough Systems

Controlled reaction during thawing & baking.

Meat & Seafood

Water retention support in injected poultry & shrimp.

Formulation Tip

A simple guideline to help R&D teams quickly dial in performance for double-acting systems.

💡 Pro Tip: Optimizing Your Leavening System

For a balanced double-acting system in muffins:

Use SAPP (slow) + SAS (fast) at a 70:30 ratio Total leavening acid : NaHCO₃ = 1 : 1.2 (by neutralizing value)

Note: ratios depend on flour strength, water activity, process temperature profile, and target texture.

What You’ll Receive

- TDS (typical specs & test methods)

- COA (batch results incl. heavy metals & fluoride)

- SDS (GHS format)

- Packaging & loading plan (upon request)

Compliance Notes

We support export documentation and customer audits as needed. Please share your destination market and internal

compliance requirements, and we will align the document pack accordingly.

Request Technical Data Pack

Tell us your application (bakery/meat/other), target spec standard (GB/FCC/etc.), and destination country.

We’ll send TDS/COA/SDS and recommended grades.

Free Sample for Trial

For qualified industrial users. Share your trial plan and required quantity. We’ll confirm availability and shipping options.

Trust & Supply Assurance

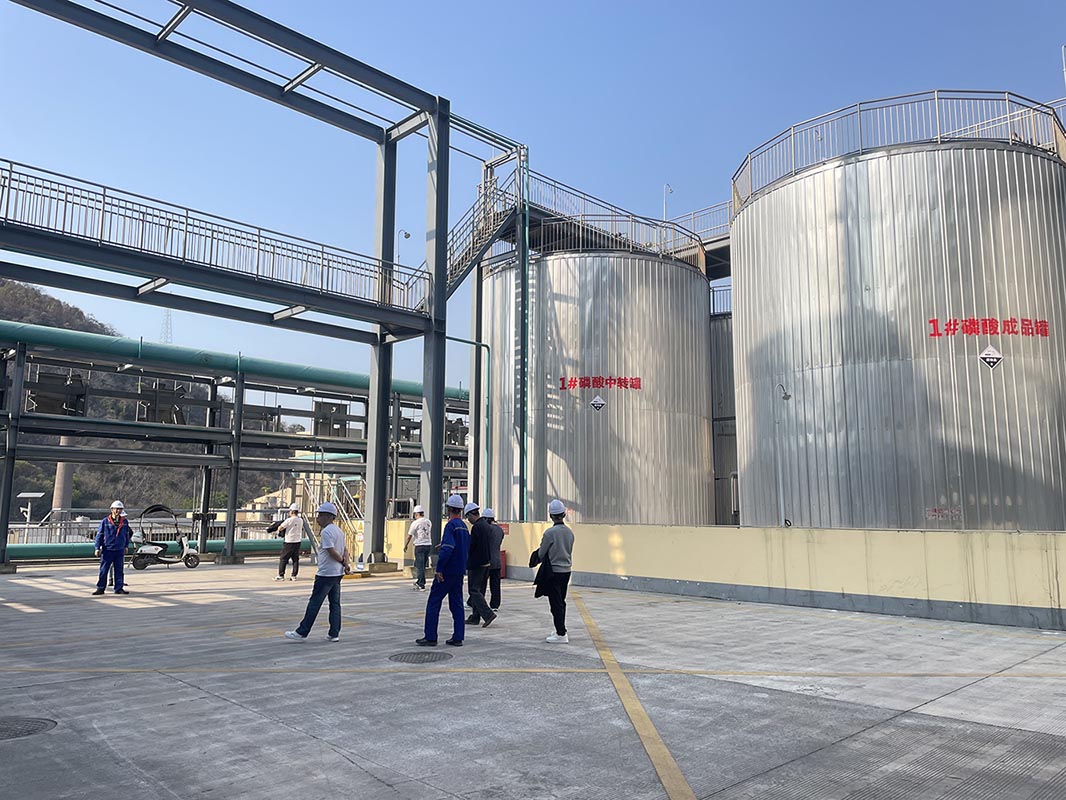

Dedicated Food-Grade Facility

Produced in a dedicated FSSC 22000 management system facility (documentation available upon request).

Full Batch Traceability

Full batch traceability from raw material to finished goods, with retained samples and QC records.

Packaging & Loading

Standard: 25kg multi-wall paper bag with PE liner, palletized. Other packaging available upon request.

Goway Food-Grade Phosphate Production Line

We support customer audits and provide documentation packs tailored to your region (US / EU / SEA).

Share your target application, and we will recommend the best fit SAPP grade and usage guidance.

FAQ

What documents can you provide for SAPP?

Typically: TDS, COA, SDS, packaging spec, loading plan, and supporting compliance documents (upon request).

Can you meet FCC / GB standards?

We can align specification and test methods based on your destination market and compliance requirements.

Please tell us your standard and application.

What is the standard packaging?

Standard packaging is 25kg multi-wall paper bag with PE liner, palletized. Other options can be provided upon request.