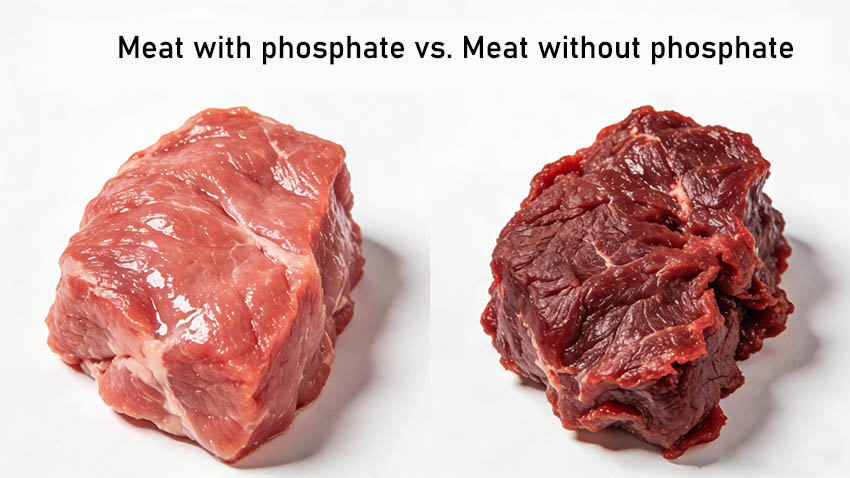

Reduce Cooking Loss by 15% and Eliminate Dry Texture — with Precision Phosphate Blends

Goway’s food-grade STPP, SHMP, and TSPP are formulated to lock in moisture, improve protein binding, and maximize yield — from frozen shrimp to sliced deli meats.

Looking for the seafood deep dive? See our authoritative guide: Enhancing Seafood Quality with Phosphates →